L7032 Continuous Forms Laser

| L7032 Continuous Forms Laser |

Printronix L7032 |  |

Designed specifically for high volume mission critical applications, each consumable or service item delivers extended life. L7032 delivers a powerful combination of speed, ease of use, small foot print, high workload, flexible media handling and affordability. Rated at 32 pages per minute and up to 400,000 pages per month, this printer is ideal for use in distribution, supply chain and manufacturing applications. Long life coupled with extreme ease of use creates a print solution that reliably delivers high volume throughput.

High speed 32 PPM / 1650 lines per minute

Forms Flexibility - straight paper path and robust / precise tractor drive. Handles tough labels, tag and card stock without jams and misalignment.

Wide paper path - up to 15.5- media and 13.6- print width

High image quality - 600 DPI

Low cost per page - best in the LaserLine family

High workload - rating of 400,000 pages per month

Simple and reliable heat and pressure fusing

Ease of Use - All consumables and service items can replaced in minutes without tools or special training

Wide range of options - Power Assist Stacker, Full Power Stacker, Cutter, Cabinet Stand, MICR

Cabinet StandThis stand elevates the printer to a comfortable working height. Wheels provide for easy movement and a paper shelf holds the input media safely off the ground. The cabinet area provides for convenient storage of additional consumables and media. | |

Developer UnitIncludes developing unit. Yield - 800,000 pages. | |

OPC Drum KitIncludes OPC drum cartridge, main charger unit, and charger cleaner brush. Yield - 400,000 pages. | |

|

Developer UnitIncludes developing unit. Yield - 800,000 pages. | |

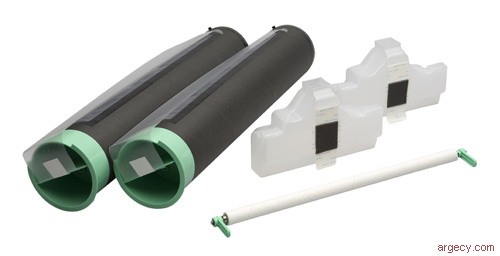

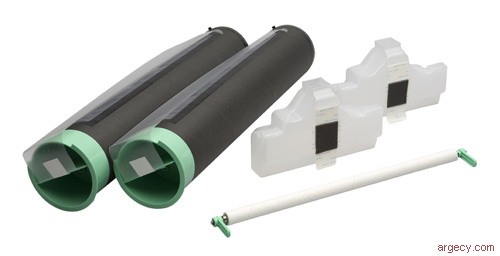

Toner KitIncludes 2 toner bottles, 2 toner waste containers, and 1 fuser cleaning roller. Yield - 64,000 pages (2 @ 32,000 pages | |

Toner KitIncludes 2 toner bottles, 2 toner waste containers, and 1 fuser cleaning roller. Yield - 64,000 pages (2 @ 32,000 pages | |

Developer MixIncludes developer powder, ozone filter, 5 clearer swabs, 5 cleaner wipes, a drop cloth, and developer mix disposal bag. Yield - 800,000 pages. | |

Developer MixIncludes developer powder, ozone filter, 5 clearer swabs, 5 cleaner wipes, a drop cloth, and developer mix disposal bag. Yield - 800,000 pages. | |

| |

Fuser Assembly Includes fuser and fuser roller. There are separate models for each voltage range: 120 VAC and 220 VAC. Yield - 800,000 pages. | |

CutterA cutter option is available to make separating jobs automatic. This is an actual cutter and not simply a perforation separator. So, even if many jobs are sent to the printer in a row before retrieval, they will all be waiting correctly separated for distribution. The printer-s reverse feed capabilities enables jobs to be cut and separated without wasting forms in between. | |

Power Assist StackerPrintronix continuous form laser printers can handle challenging media and challenging media often requires help stacking. In most cases, the Power Assist Stacker is the ideal solution. At an attractive price point, this makes stacking most media possible. Requires the optional stand. | |

CutterA cutter option is available to make separating jobs automatic. This is an actual cutter and not simply a perforation separator. So, even if many jobs are sent to the printer in a row before retrieval, they will all be waiting correctly separated for distribution. The printer-s reverse feed capabilities enables jobs to be cut and separated without wasting forms in between. | L7032 CUTTER OPTION - Factory installed New PRI-251750-001 (New) Retired, no longer available: Contact for alternatives |

Full Power StackerAlthough sufficient for most applications, some media types will prove too severe for the Power Assist Stacker. Synchronized with the form-s natural pattern of folds, this solution actively guides the form to refold in its natural sequence. Pinch rollers provide the necessary drive energy to draw these forms from the printer, past the guides, and down into the stacking area. Special designed fingers apply pressure to the edges of the fold to ensure the stack remains tightly compressed. A moving elevator adjusts the media stack to be in correct position relative to the stacking mechanism. | |

Full Power StackerAlthough sufficient for most applications, some media types will prove too severe for the Power Assist Stacker. Synchronized with the form-s natural pattern of folds, this solution actively guides the form to refold in its natural sequence. Pinch rollers provide the necessary drive energy to draw these forms from the printer, past the guides, and down into the stacking area. Special designed fingers apply pressure to the edges of the fold to ensure the stack remains tightly compressed. A moving elevator adjusts the media stack to be in correct position relative to the stacking mechanism. | |

Full Power StackerAlthough sufficient for most applications, some media types will prove too severe for the Power Assist Stacker. Synchronized with the form-s natural pattern of folds, this solution actively guides the form to refold in its natural sequence. Pinch rollers provide the necessary drive energy to draw these forms from the printer, past the guides, and down into the stacking area. Special designed fingers apply pressure to the edges of the fold to ensure the stack remains tightly compressed. A moving elevator adjusts the media stack to be in correct position relative to the stacking mechanism. |